Expert inspection, overhaul, and repair – restoring your motor to like-new condition.

When an electric motor arrives at our workshop, it receives careful handling from the very first moment. In most cases, the customer informs us in advance that a motor is on its way for inspection. Once the motor arrives, it is registered and scheduled for evaluation.

Thorough inspection and disassembly

The motor is completely disassembled, after which our specialists clean and inspect each component. During the inspection, several measurements are performed, including:

- Electrical tests: milli-ohm and insulation measurements

- Bearing fit measurements: on both end shields (DE and NDE) and the rotor

Bearings are removed using a press or puller to allow for proper assessment and cleaning of all components.

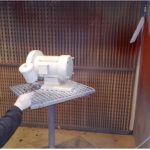

Cleaning and drying

After cleaning, the stator is carefully dried in the oven. This process prevents moisture-related issues and ensures optimal performance when the motor is reassembled.

Quotation and overhaul

Based on the inspection results, we prepare a clear quotation outlining the proposed work. Upon approval, we proceed with the overhaul of the motor, which typically includes:

- Replacing the bearings

- Coating all components

- Comprehensive testing on the test bench

Ready for a second life

After the overhaul, the motor is fully restored, thoroughly tested, and ready to perform reliably – just like new.